Liquid Miso

Production Line

Liquid Miso Production Line

-

1Bottle Forming

-

Liquid Miso Bottle Forming Machine

These mold bottles are for liquid miso. A workpiece, called a preform, is heated and inflated with air, to mold it into a bottle.

Static Electricity Eliminator

This machine eliminates static electricity, making it easier to remove dirt and dust from the inside of each bottle.

Dust Collector

Dirt and dust are sucked out from the inside of each bottle.

-

2Packaging

-

Liquid Miso Filling Machine

While being measured, each bottle is filled with a specified amount of liquid miso.

-

3Attach cap

-

Cap Sealing Machine

This machine screws and seals caps onto bottles.

-

4Inspect cap direction

-

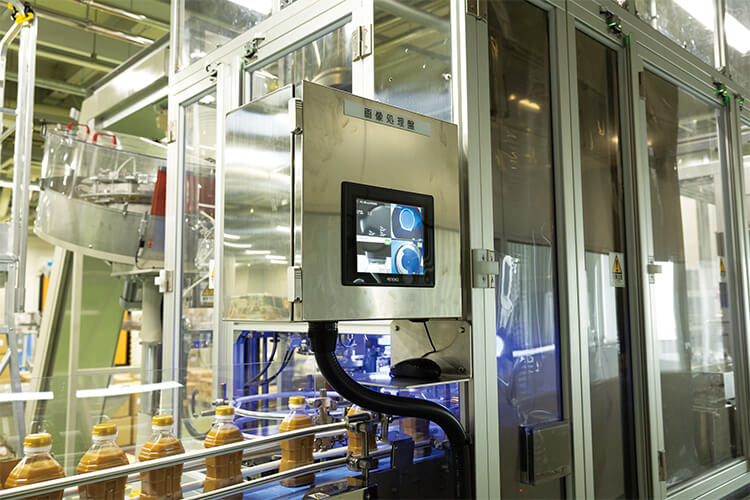

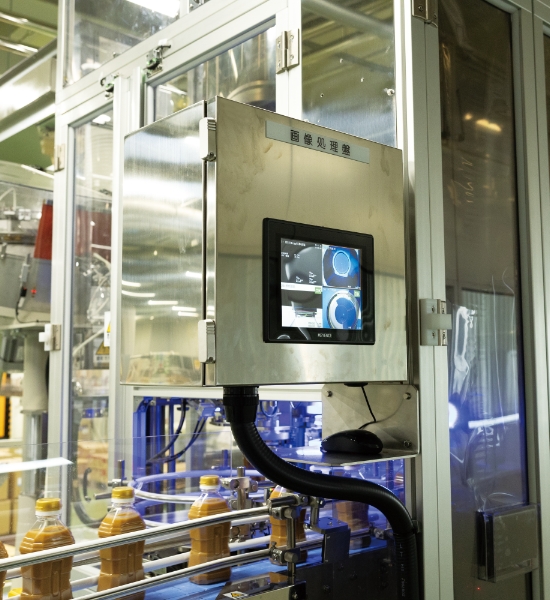

Image Inspection Device for Caps

This deviced is used for checking whether caps are attached properly.

-

5Attach film

-

Sleeve Label Wrapping Machine

After checking whether a best-before date has been printed on each label appropriately, this machine wraps each bottle with the label.

Sleeve Label Shrinking Machine

This shrinks a sleeve label with steam, to attach it to a bottle.

Water Removing Machine

Water droplets on bottles are removed with air.

-

6Inspect package gap

-

Image Inspection Device for Labels

Each label is checked if it is correct and in place.

-

7Inspect X-Ray

-

X-Ray Contamination Detector

The detector is used to irridiate products with x-ray to check for foreign matters, such as glass or metal.

-

8Inspect weight (package)

-

Weight Checker

The weight of each product is measured to confirm that it matches with our specs.

-

9Image inspection

-

Image Inspection Device for Barcode

The barcodes are checked to ensure that other products are not mixed into the same production line.

-

10Pack into boxes

-

Machine for Putting Products Into Boxes

This machine forms the cardboard box while packing products into it.

-

11Best-before date printing (case)

-

Best-Before Date Printer

Best-before date is printed on each case.

Image Inspection Device for Cases

The best-before date is checked to make sure that the date has been printed properly and that there is no dent or distortion.

-

12Shipment

-

Weight Checking

Elevator

The elevator checks the weight of each case. After confirming, the elevator transports the product down to the first floor.

Pallet Stacker

The pallet stacker puts the product boxes on the pallet.

Wrapping Machine

The cargoes are wrapped to prevent the cargo from shifting during transportation.

Shipment

After loading the cargoes onto the truck, it's finally time to ship them.

-

Why are the bottles shaken?

-

A.In order to prevent the deformation of the bottle that could occur due to the heat inside a steam tunnel, we shake the bottles to make miso adhere to the whole area of each bottle and reduce the direct heat transfer onto the bottles.