Koji Room

Let's look at the place where Koji is made!

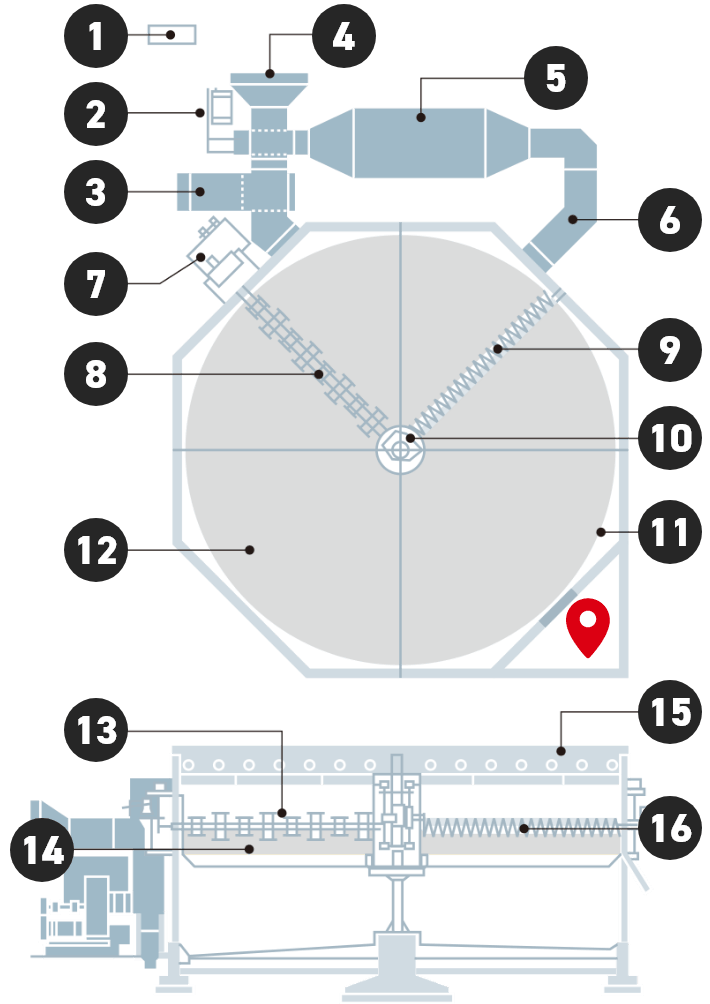

Disk-Shaped Machine for Koji Production

Please tap the number

Koji Making Processes

Source: "Recipe for Sugar-free Koji Jam with Natural Sweetness,"1Incoming Supply of Rice

Rice that passed inspection is delivered in one-ton bags.

2Polishing

The delivered rice is polished to remove the bran.

3Sorting

Discolored rice and foreign materials, such as stones, are removed by using a machine designated for color sorting, called Final Sorter.

4Soaking

The rice is placed in the tank and soaked in water for a certain length of time, so that the rice will absorb the water all the way to its core.

5Steaming

Rice is drained and steamed until it reaches the state where the outside of the rice grain is hard but the inside is soft.

6Cooling

The steamed rice is cooled to a temperature appropriate for Koji production.

7Inoculation

Powdered Koji mold is sprayed on the cooled rice.

8Levelling

Rice is brought into the disc-shaped Koji making chamber and then levelled evenly.

9Koji Production

Koji production takes 48 hours.

Koji is grown under in a temperature and humidity-controlled chamber while maintaining an air supply (agitation).

Rice becomes Koji slowly over time.

1Control Panel

2Air Blower

3Damper

4Plate Fin Heater

5Air Conditioner

6Air Duct

7Disc-Driving Unit

8Manual Input Device

9Machine for Loading and Unloading

10Central Cylinder

11Sidewall

12Rotating Disc with Base Plate

13Manual Input Device

14Rotating Disc with Base Plate

15Koji-Making Room

16Machine for Loading and Unloading

Observation room